Identify three specific criteria for determining when a process is out of statistical control.

Table of contents

- 1. Intro to Stats and Collecting Data1h 14m

- 2. Describing Data with Tables and Graphs1h 56m

- 3. Describing Data Numerically2h 5m

- 4. Probability2h 16m

- 5. Binomial Distribution & Discrete Random Variables3h 6m

- 6. Normal Distribution and Continuous Random Variables2h 11m

- 7. Sampling Distributions & Confidence Intervals: Mean3h 23m

- Sampling Distribution of the Sample Mean and Central Limit Theorem19m

- Distribution of Sample Mean - Excel23m

- Introduction to Confidence Intervals15m

- Confidence Intervals for Population Mean1h 18m

- Determining the Minimum Sample Size Required12m

- Finding Probabilities and T Critical Values - Excel28m

- Confidence Intervals for Population Means - Excel25m

- 8. Sampling Distributions & Confidence Intervals: Proportion2h 10m

- 9. Hypothesis Testing for One Sample5h 8m

- Steps in Hypothesis Testing1h 6m

- Performing Hypothesis Tests: Means1h 4m

- Hypothesis Testing: Means - Excel42m

- Performing Hypothesis Tests: Proportions37m

- Hypothesis Testing: Proportions - Excel27m

- Performing Hypothesis Tests: Variance12m

- Critical Values and Rejection Regions28m

- Link Between Confidence Intervals and Hypothesis Testing12m

- Type I & Type II Errors16m

- 10. Hypothesis Testing for Two Samples5h 37m

- Two Proportions1h 13m

- Two Proportions Hypothesis Test - Excel28m

- Two Means - Unknown, Unequal Variance1h 3m

- Two Means - Unknown Variances Hypothesis Test - Excel12m

- Two Means - Unknown, Equal Variance15m

- Two Means - Unknown, Equal Variances Hypothesis Test - Excel9m

- Two Means - Known Variance12m

- Two Means - Sigma Known Hypothesis Test - Excel21m

- Two Means - Matched Pairs (Dependent Samples)42m

- Matched Pairs Hypothesis Test - Excel12m

- Two Variances and F Distribution29m

- Two Variances - Graphing Calculator16m

- 11. Correlation1h 24m

- 12. Regression3h 33m

- Linear Regression & Least Squares Method26m

- Residuals12m

- Coefficient of Determination12m

- Regression Line Equation and Coefficient of Determination - Excel8m

- Finding Residuals and Creating Residual Plots - Excel11m

- Inferences for Slope31m

- Enabling Data Analysis Toolpak1m

- Regression Readout of the Data Analysis Toolpak - Excel21m

- Prediction Intervals13m

- Prediction Intervals - Excel19m

- Multiple Regression - Excel29m

- Quadratic Regression15m

- Quadratic Regression - Excel10m

- 13. Chi-Square Tests & Goodness of Fit2h 21m

- 14. ANOVA2h 28m

1. Intro to Stats and Collecting Data

Intro to Stats

Problem 14.2.5

Textbook Question

Control Charts for p. In Exercises 5–12, use the given process data to construct a control chart for p. In each case, use the three out-of-control criteria listed near the beginning of this section and determine whether the process is within statistical control. If it is not, identify which of the three out-of-control criteria apply.

Euro Coins Consider a process of minting coins with a value of one euro. Listed below are the numbers of defective coins in successive batches of 10,000 coins randomly selected on consecutive days of production.

32 21 25 19 35 34 27 30 26 33

Verified step by step guidance

Verified step by step guidance1

Step 1: Calculate the sample proportion (p̂) for each batch. The sample proportion is calculated as the number of defective coins divided by the total number of coins in each batch. For each batch, use the formula: p̂ = (Number of Defective Coins) / (Total Coins in Batch).

Step 2: Compute the overall proportion (p̄) of defective coins across all batches. This is done by summing up all the defective coins across batches and dividing by the total number of coins across all batches. Use the formula: p̄ = (Total Defective Coins) / (Total Coins in All Batches).

Step 3: Calculate the standard error (SE) for the control chart. The standard error is given by the formula: SE = sqrt((p̄ * (1 - p̄)) / n), where n is the sample size (10,000 coins per batch in this case).

Step 4: Determine the control limits for the control chart. The upper control limit (UCL) and lower control limit (LCL) are calculated as follows: UCL = p̄ + 3 * SE and LCL = p̄ - 3 * SE. If LCL is negative, set it to 0 since proportions cannot be negative.

Step 5: Plot the sample proportions (p̂) for each batch on the control chart and compare them to the control limits. Identify any points that fall outside the control limits or patterns that meet the three out-of-control criteria (e.g., a single point outside the control limits, a run of points on one side of the centerline, or a trend). Determine whether the process is in statistical control based on these criteria.

Verified video answer for a similar problem:

Verified video answer for a similar problem:This video solution was recommended by our tutors as helpful for the problem above

Video duration:

5mPlay a video:

0 Comments

Key Concepts

Here are the essential concepts you must grasp in order to answer the question correctly.

Control Charts

Control charts are statistical tools used to monitor the stability of a process over time. They display data points in time order and include control limits that indicate the expected variation in the process. By analyzing these charts, one can determine if a process is in control or if there are signs of variation that may indicate problems.

Recommended video:

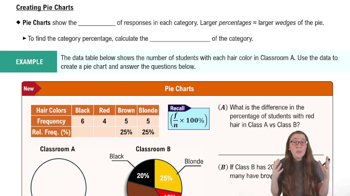

Creating Pie Charts

Out-of-Control Criteria

Out-of-control criteria are specific rules used to identify when a process is exhibiting unusual variation that may indicate it is not operating as expected. Common criteria include points falling outside control limits, a run of consecutive points above or below the centerline, or a trend of points moving in one direction. These criteria help in diagnosing potential issues in the process.

Recommended video:

Guided course

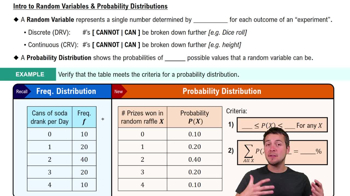

Intro to Random Variables & Probability Distributions

Defective Rate (p)

The defective rate, often denoted as 'p', represents the proportion of defective items in a sample. In the context of control charts, it is calculated by dividing the number of defective items by the total number of items inspected. Monitoring the defective rate helps in assessing the quality of the production process and determining if it remains within acceptable limits.

Recommended video:

Guided course

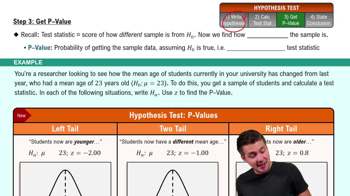

Step 3: Get P-Value

2:13m

2:13mWatch next

Master Introduction to Statistics Channel with a bite sized video explanation from Patrick

Start learningRelated Videos

Related Practice

Textbook Question

1

views