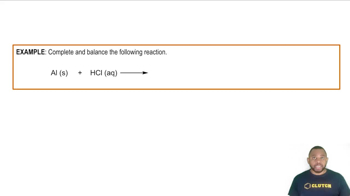

Textbook Question

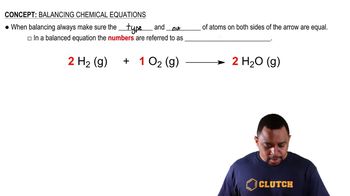

Write balanced equations for the formation of the following compounds from their elements.(c) Uranium hexafluoride (a solid at 25 °C)

Verified step by step guidance

Verified step by step guidance

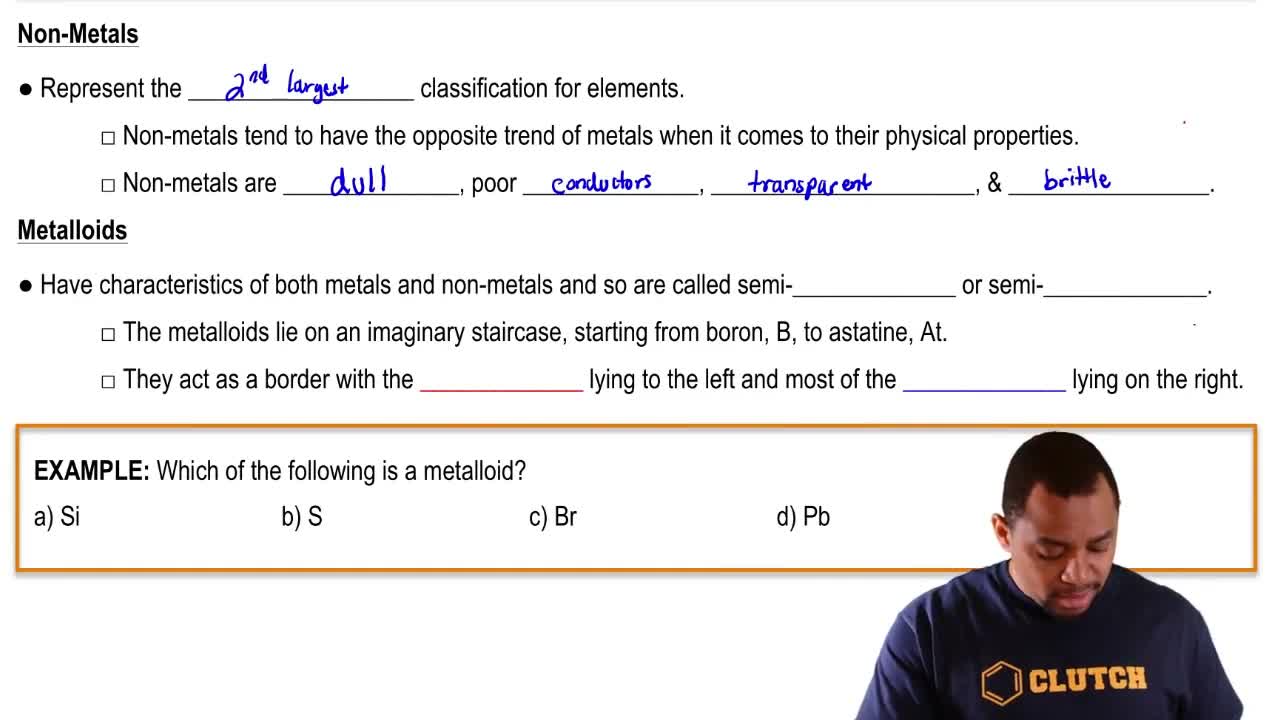

Identify the group 4A element that best fits each of the following descriptions.

(c) Is the second most abundant element in the Earth's crust

Select the group 4A element that best fits each of the following descriptions.

(c) Is the second most abundant element in the human body